The so-called button cells are being used more and more and are contained in remote controls, LED tea lights, key rings, kitchen scales etc. If a battery runs out, you usually don’t buy just one battery, but a set.

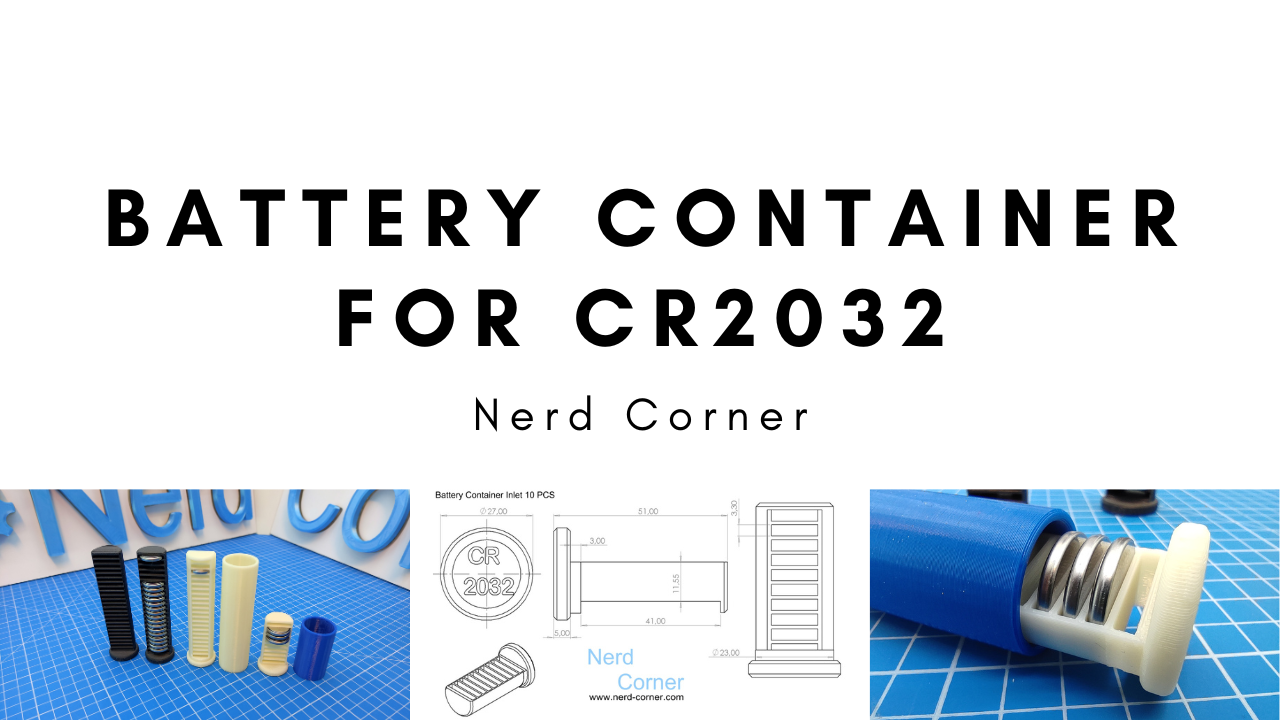

To organise the workshop, I have developed a storage box for CR2032 and similar batteries of this type. There are already a few, but they all had the same shortcoming. The battery containers for CR2032 must always be opened with the proper side facing upwards, otherwise everything falls onto the floor. My battery cases for the CR2032 offer safe and clean storage without the cells falling out. In addition, you always have an overview of the number of batteries present.

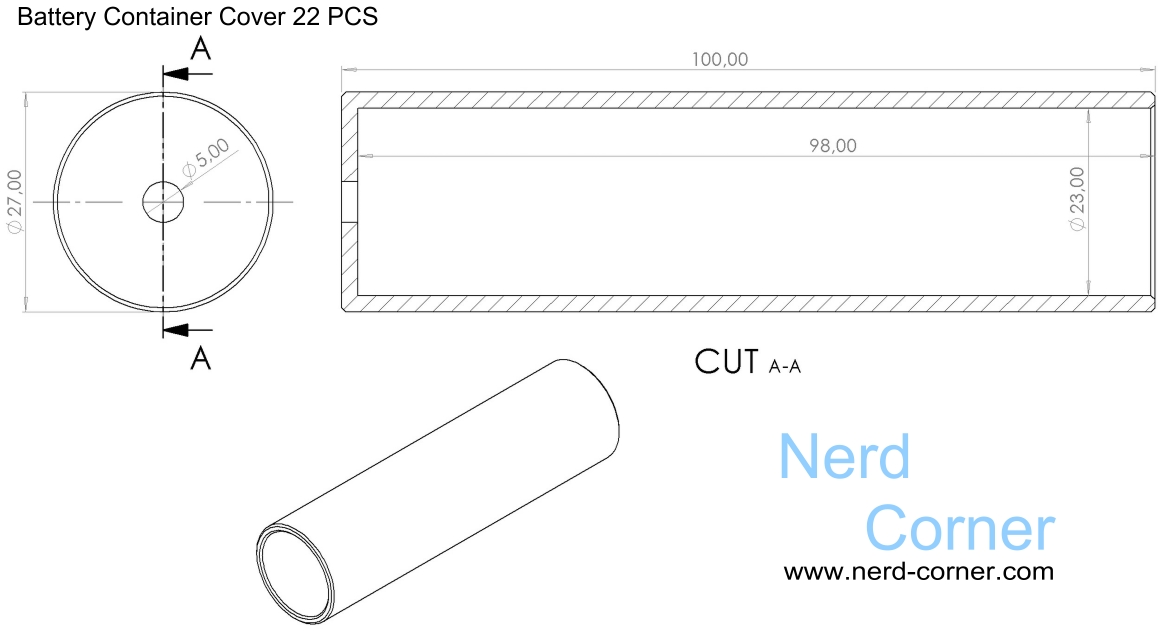

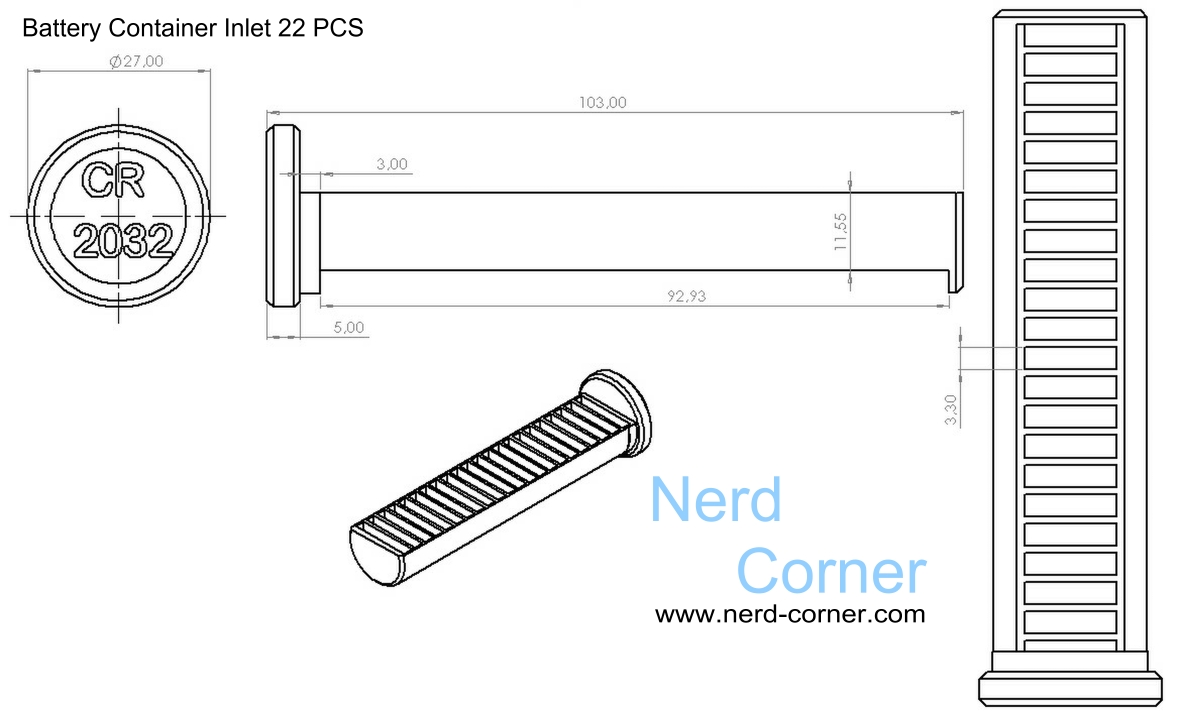

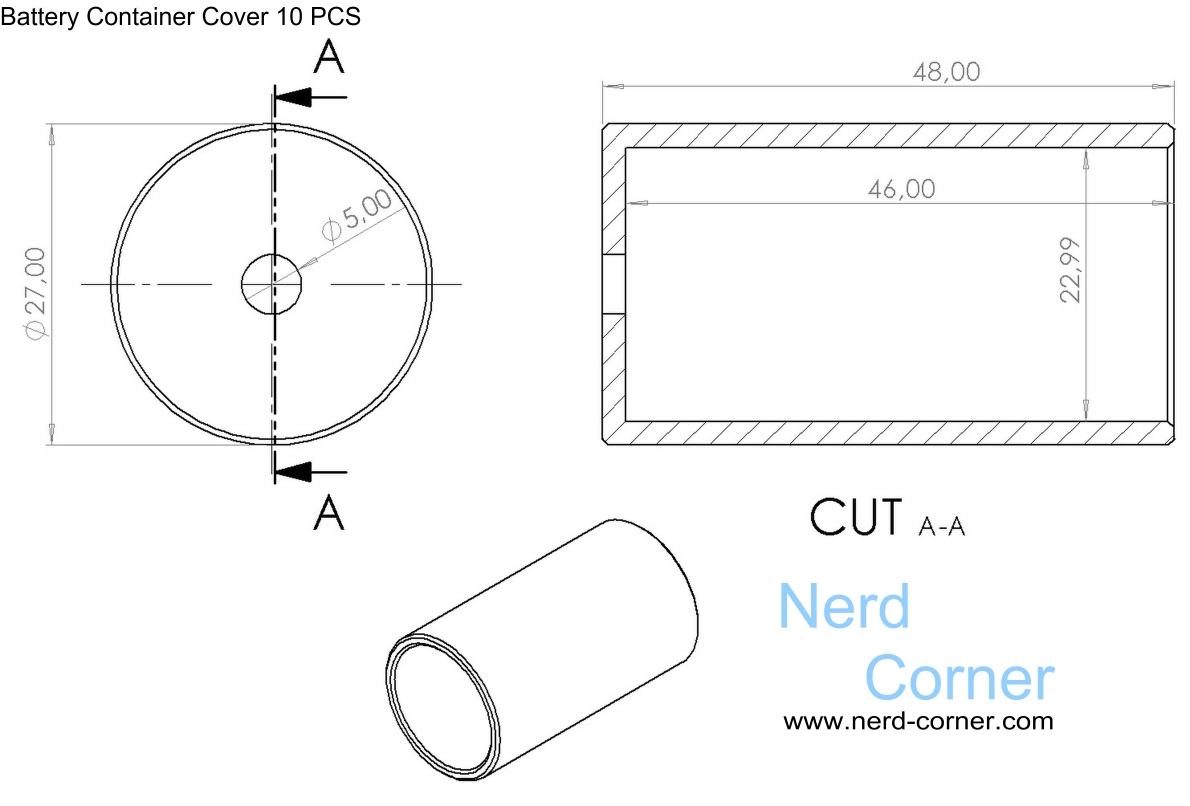

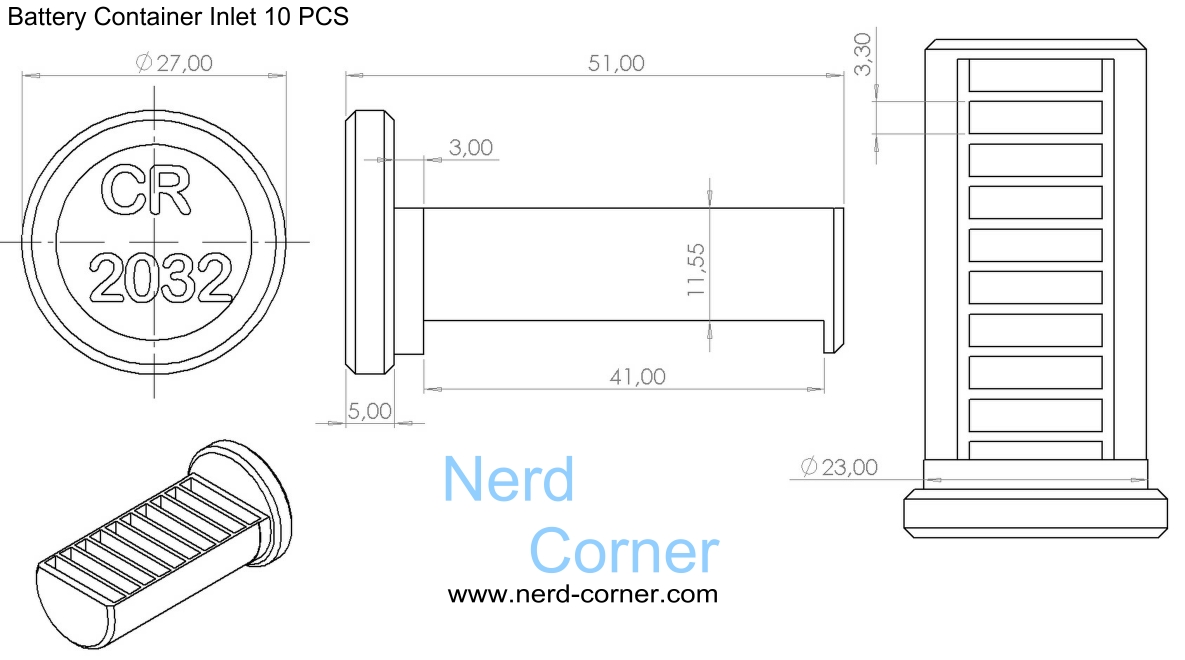

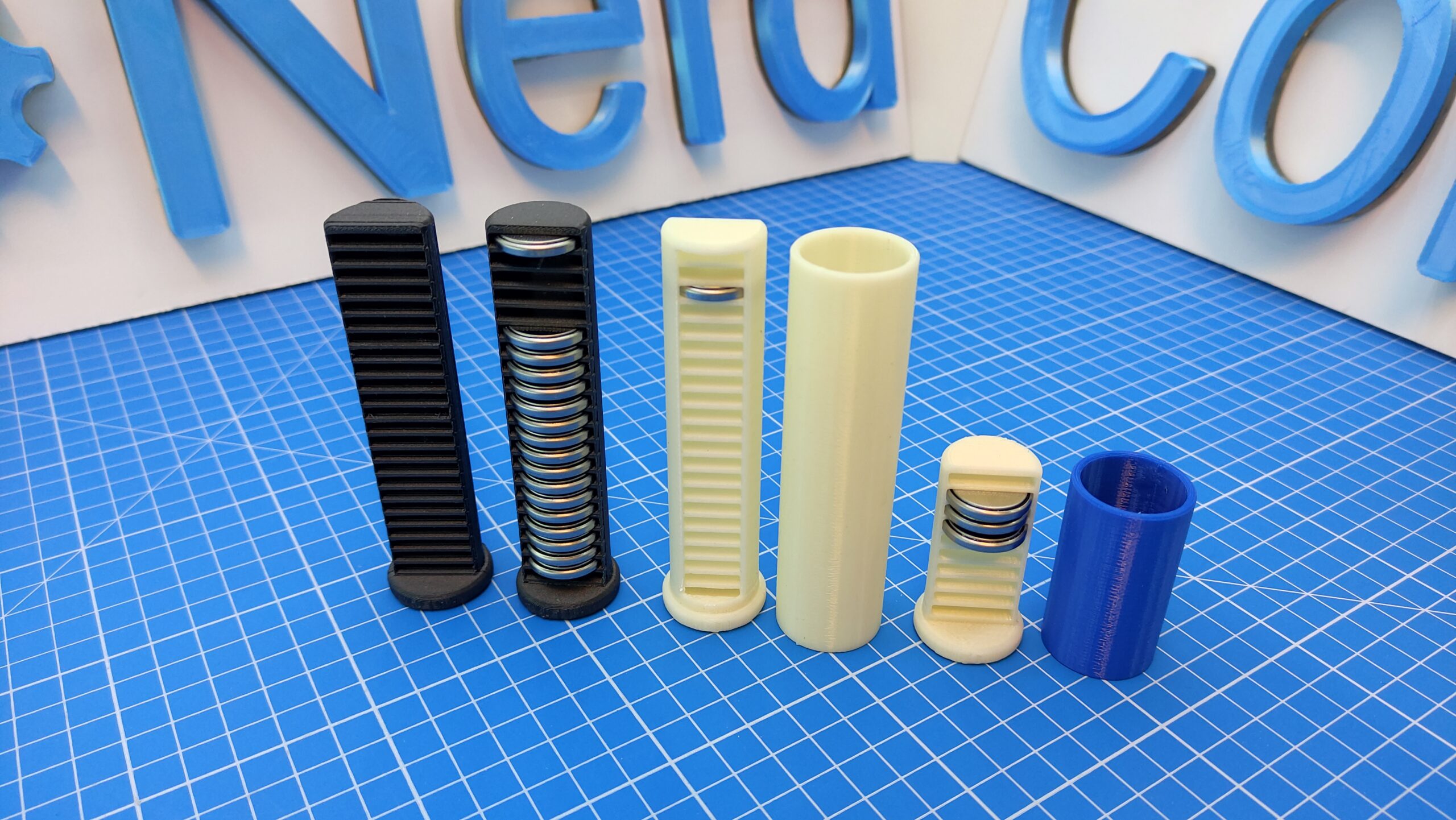

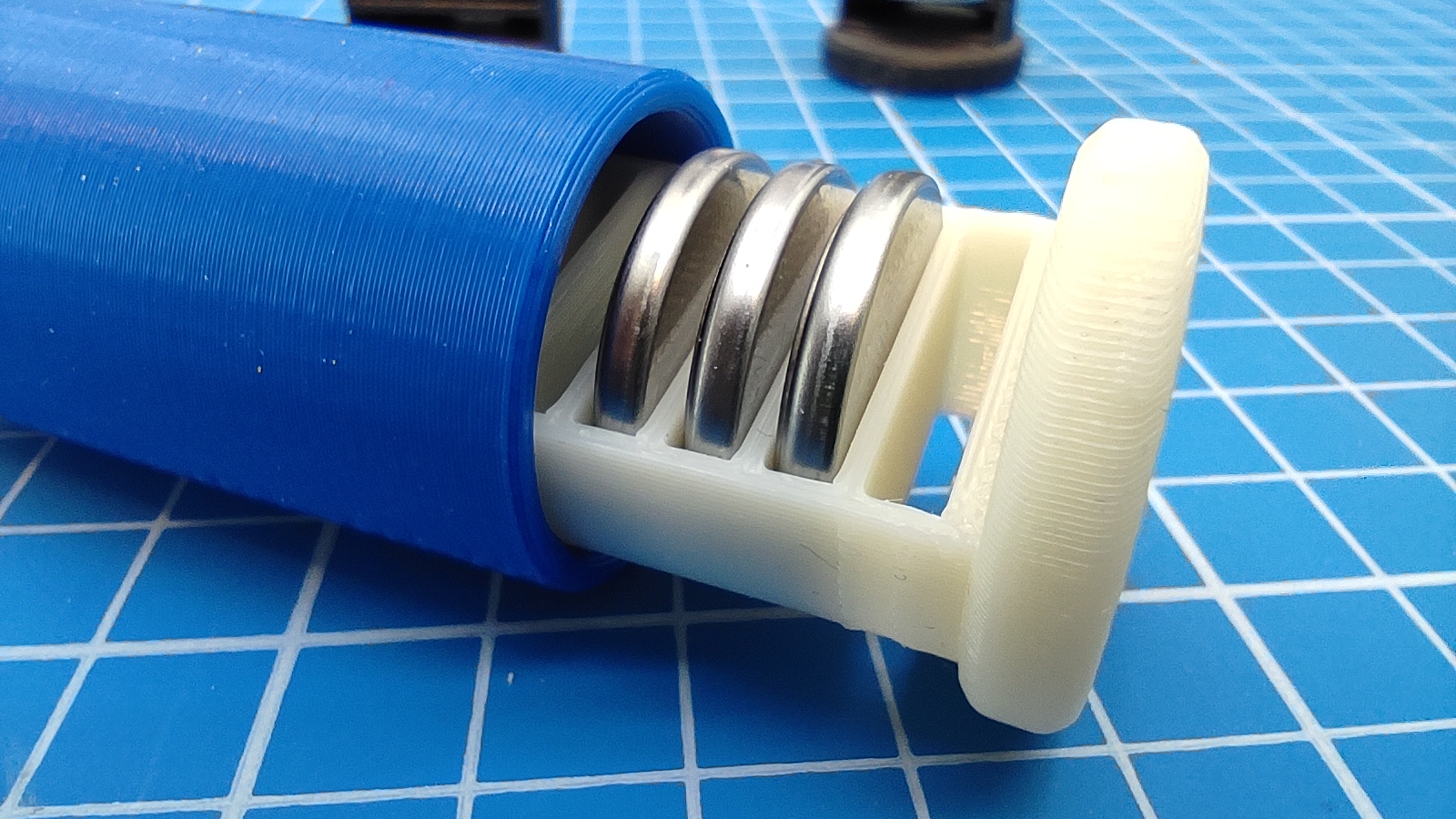

The container is available in 2 versions, one for 10 and one for 22 button cells. The container consists of a drawer and a cover (container) and is safe against shocks and falls. The batteries are simply clicked into place and hold firmly in their drawer.

You might also be interested in: 3D printed Dupont connector

Construction of battery container CR2032

The container must be stable and durable, but still have handy dimensions. In addition, each individual battery must sit firmly in its compartment and yet be easy to remove. I also asked myself how many batteries the battery container for the 2032 should actually contain. Most sets consist of 5, 6, 8 or 10, sometimes even 20. In any case, the container had to fit in my desk drawer. As I was not sure about the number of batteries to be stored, I decided on two variants, one with 10 pieces and one with 22 pieces.

The construction on the CAD starts with the drawer, i.e. the slide-in part, the long part for 22 pieces. The width of the drawer depends of course on the width of the battery, the battery is 3mm thick, 2.95mm to be exact, and needs enough air between the individual walls. A gap of 0.15-0.2mm for each side is enough to avoid friction. So if we add it all up, we get a shaft width of 3.3-3.4mm. We create the holding force that prevents the battery from falling out of the shaft with the edge trick. We create a circular pocket in the centre of the slot with a larger diameter than the battery. Then we cut off about 1 to 3 mm of the material above the centre point, thus creating an edge. This edge must be slightly smaller in absolute length than the diameter of the battery (in this case smaller than 20mm). If you now push the battery into the shaft, it must overcome the edge, which is also possible due to the elasticity of the material.

Now the battery sits in the shaft and cannot overcome the edge in the other direction with its own weight. This principle is actually quite simple, with the necessary knowledge about material, manufacturing tolerances, forces and holding torques. In the end, it was a mixture of experience and a few test prints until the optimum result was achieved. Now the battery fits neatly into the shaft and holds perfectly. And with gentle pressure, the battery can also be removed from the shaft again.

The next goal was to design the slot so that it holds securely in the case. This is also an interaction of material elasticity and the right diameter at the collar that holds the construction together. After a few test pressings, I was satisfied.

The shell of the CR2032 battery container is quickly constructed. Basically, it is a cylinder with a base. The inner diameter was adapted to the insertion size to ensure locking and the hole in the bottom of the sleeve is for air release, because when the insertion is pushed into the sleeve, the air must be able to escape.